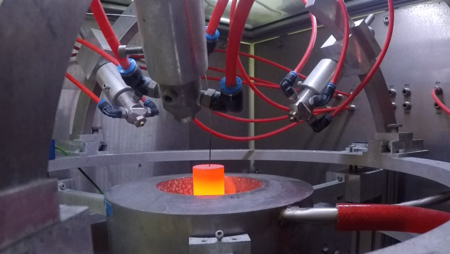

Self-developed 2-zone spray field for investigations for sensor-based in-situ detection of material transformations and microstructure formation in cylindrical samples and real components. In this test stand, samples and components can be cooled from the austenitization temperature in a defined manner and the microstructure formation can be recorded in parallel using an electromagnetic method.

Technical details:

- Up to 12 water-air spray nozzles

- Cooling control: sequence-controlled, temperature-controlled, eddy current sensor-controlled

- Temperature detection via thermocouples and integrated pyrometers

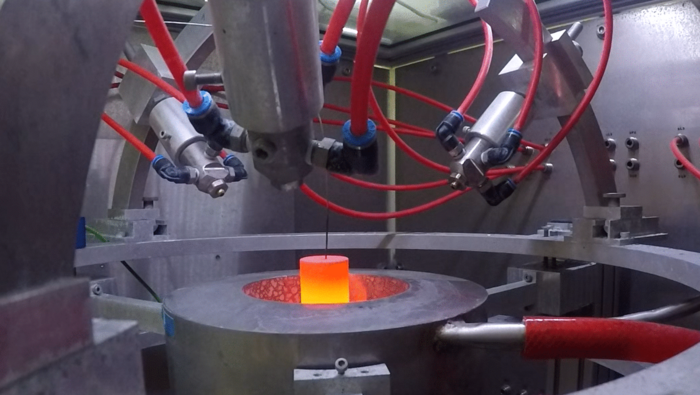

Self-developed 2-zone spray field for investigations for sensor-based in-situ detection of material transformations and microstructure formation in cylindrical samples and real components. In this test stand, samples and components can be cooled from the austenitization temperature in a defined manner and the microstructure formation can be recorded in parallel using an electromagnetic method.

Technical details:

- Up to 12 water-air spray nozzles

- Cooling control: sequence-controlled, temperature-controlled, eddy current sensor-controlled

- Temperature detection via thermocouples and integrated pyrometers

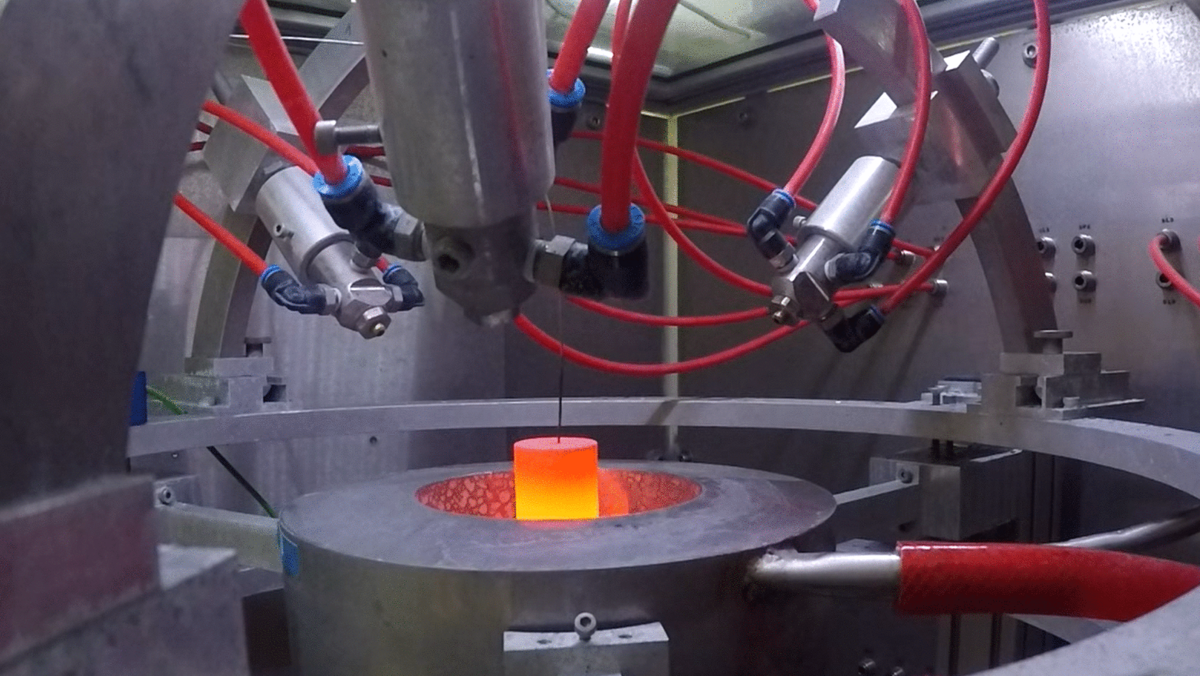

Technical Details

- Up to 12 water-air spray nozzles

- Cooling control: sequence-controlled, temperature-controlled, eddy current sensor-controlled

- Temperature detection via thermocouples and integrated pyrometers

30823 Garbsen