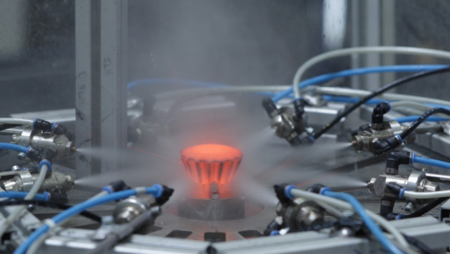

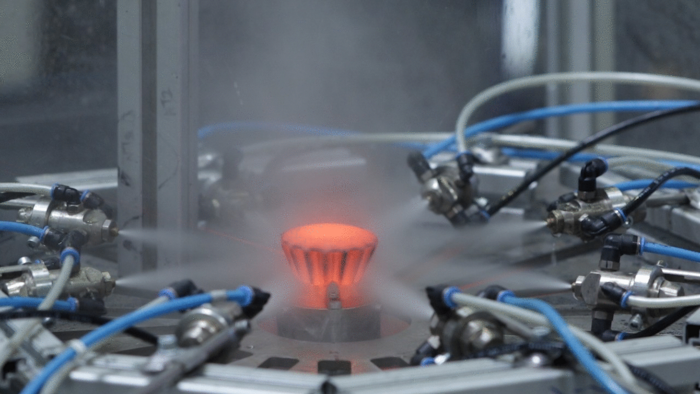

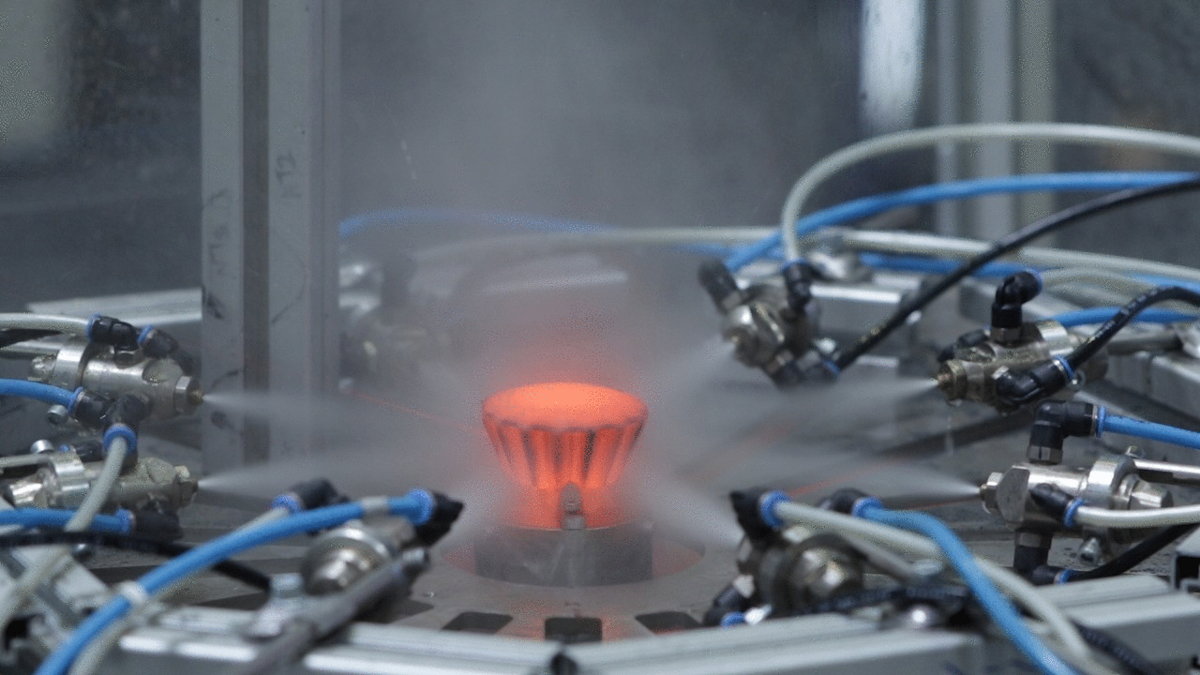

Air-water spray cooling

In air-water spray cooling, a jet of water is atomized by compressed air in a two-substance nozzle and accelerated in the direction of the surface to be cooled. This results in an increase in the high Leidenfrost and burn-out temperatures, controllable quenching intensities thanks to precisely adjustable media inlet pressures and the possibility of locally adapted heat treatment.

In air-water spray cooling, a jet of water is atomized by compressed air in a two-substance nozzle and accelerated in the direction of the surface to be cooled. This results in an increase in the high Leidenfrost and burn-out temperatures, controllable quenching intensities thanks to precisely adjustable media inlet pressures and the possibility of locally adapted heat treatment.

Technical equipment

- Spray cooling systems with different nozzle configurations

- Use of internally mixing two-substance nozzles

- Heat treatment of various component geometries

- Simulation-based design of heat treatment strategies

- Local adaptation of cooling using independent control circuits

- Induction hardening possible in combination with induction heating systems

- Programmable cooling regimes for advanced temperature control

- Contact and non-contact temperature control

30823 Garbsen